Robotics

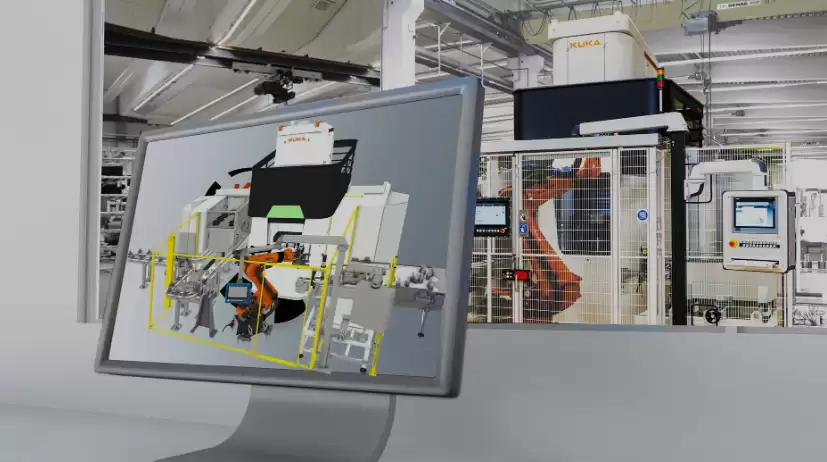

We integrate many robot brands ( FANUC, STAUBLI, OMRON, ADEPT, YAMAHA, KUKA, ABB...).

We specialize in :

- assembly systems,

- palletizing, depalletizing,

- component removal,

- tracking,

- welding.

Vision and robotics

These technologies are particularly well suited to very high production rates. Integrated and/or customized vision solutions, developed by our vision & robotics experts.

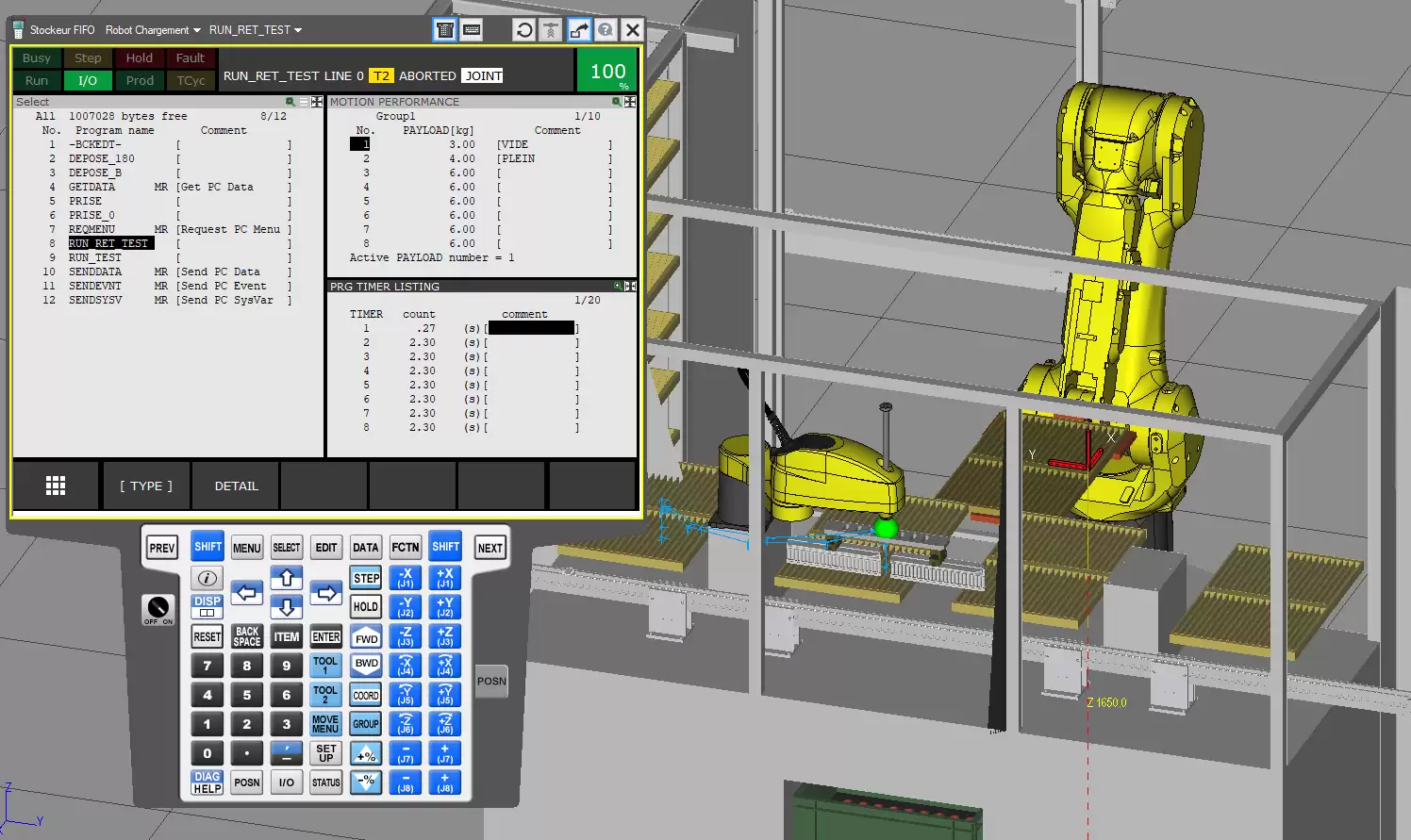

Digital simulation tools

Industrial robotics simulation tools offer a range of functionalities that enable companies to optimize the design, programming and operation of robotic systems in a wide range of industrial applications.

On a daily basis, we use the most common numerical simulation tools, such as Roboguide - KukaSim - Staublï Robotics Suite - Process Simulate - ACE Omron. These indispensable tools enable our team to :

Robot cell design and validation: Simulation tools can be used to design and validate complete robot cells, including not only the robots themselves, but also peripheral devices such as conveyors, sensors, actuators and so on. This ensures that the cell layout is optimal and that the robots can perform their tasks efficiently.

Offline programming (PHL): Simulation tools enable engineers to program robot movements offline, i.e. without the need for physical access to real robots. This reduces machine downtime and optimizes productivity.

Trajectory optimization: simulation tools can be used to optimize robot trajectories to minimize cycle times, avoid collisions and optimize workspace utilization.

Operator training: Simulation tools can be used to train operators to use robots and associated equipment in a virtual environment without risk to people or equipment.

Performance analysis: Simulation tools can be used to analyze the performance of robotic systems by simulating different operating conditions and evaluating the results obtained.

Integration with other systems: Simulation tools can be used to simulate the interaction between robots and other automated systems, such as machine tools, vision systems, process control systems and so on.

In short, industrial robotics simulation tools offer a range of functionalities that enable companies to optimize the design, programming and operation of robotic systems in a wide range of industrial applications.

The industrial robolution

We firmly believe in the transformative potential of industrial robotics and cobotics in manufacturing. We actively integrate industrial robots and cobotics systems into our solutions to improve the efficiency, safety and flexibility of our production lines. Our robots are designed to work closely with human operators, boosting productivity while providing a safer, more ergonomic working environment. Thanks to our expertise in robotics, we are able to offer innovative solutions for a variety of applications, from assembly and packaging to materials handling and internal logistics. By investing in industrial robotics and cobotics, we help our customers remain competitive in a constantly evolving market, by offering modern, adaptive solutions that meet their specific manufacturing needs.

Share your projects, from the most ambitious to the most realistic, with our team